Somehow this message got lost in my inbox. So, when he says “Tues night” he’s actually referring to December 12th. Anyways, better late than never. Here is Rylan’s writeup about the new tool he made for us:

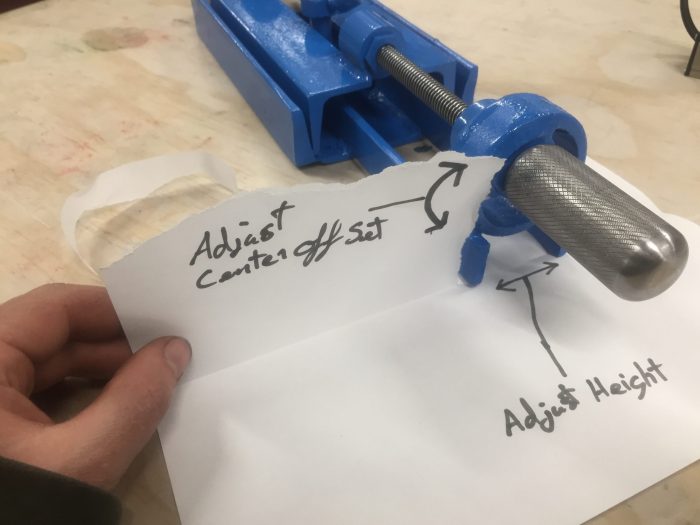

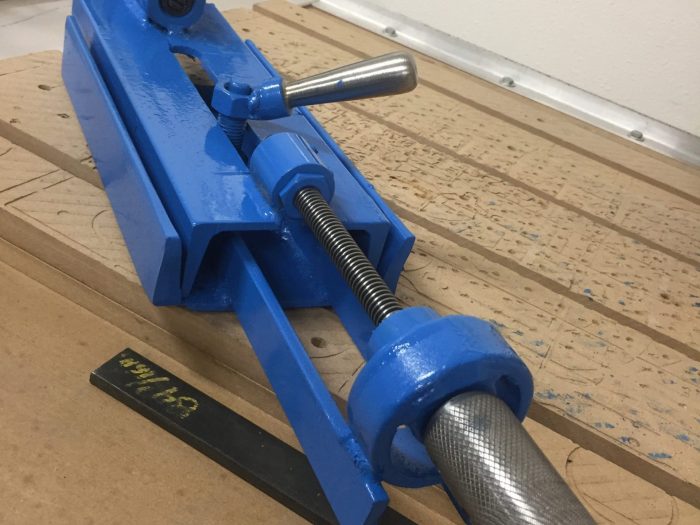

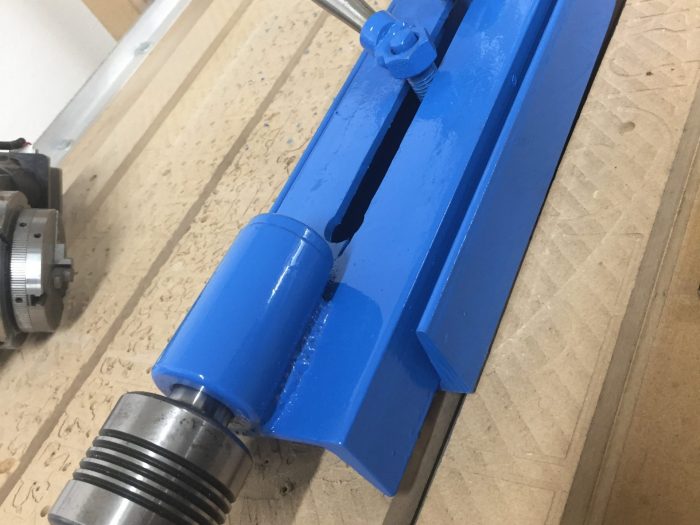

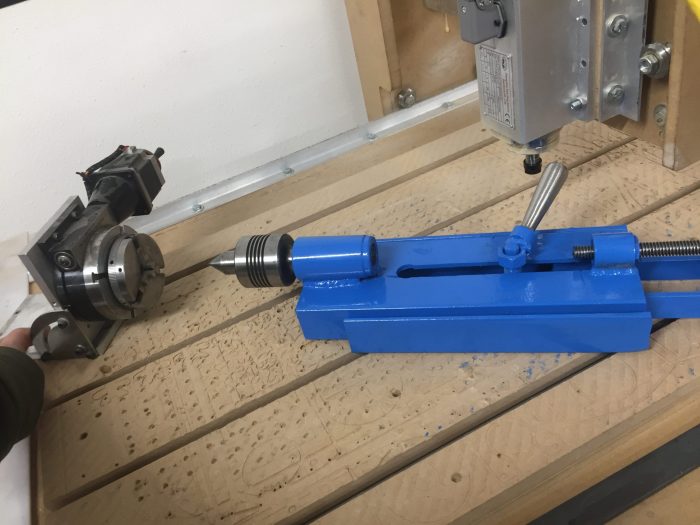

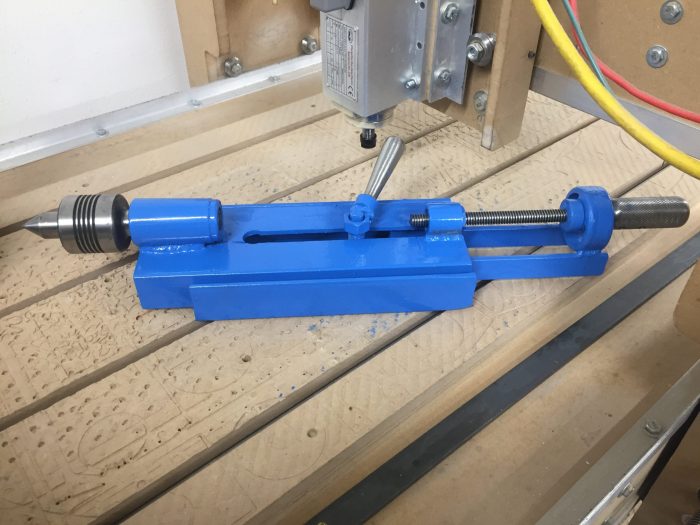

Hey everyone! On Tues night after the meeting I made a portable tail stock to match Albert’s motorized Chuck. It Took me all night but lucky I scrounged enough pieces of metal and the whole thing came together in one night — paint and all! I turned most of the parts on the lathe. My favourite part about the build was using a flexure and a clamp to adjust the height of the bushing near the handle at the back, that along with rotation of the large ring sitting on the flexure allowed me to align the back bushing very well despite the way that parts like to warp and shift as welds cool. Putting the ACME thread up on top instead of hidden underneath the carriage as is typical is a feature in this design as exposing the treads makes it them easy to clean with all the CNC cuttings.

This rotary attachment could also be easily be placed in the laser cutter and on the CNC router.

Enjoy,

Rylan