A few years ago I bought an original Bradley Smoker, thinking it would be a fun new way to prepare food. I quickly got frustrated with it. The “temperature” control was nothing more than a “dimmer” (PWM) connected to the heating element. That’s right, it wasn’t even an analogue thermostat… just an open loop. So, a gust of wind, or the sun coming over the house and hitting the unit would cause drastic changes in internal temperature. When you’re trying to cook things low and slow, a 10 degree difference is huge. So, the unit hid in the back of my garage for a few years while I thought about how I would improve it.

Finally, I got frustrated with all my grand plans to improve it that were never coming to fruition, so I took an existing “control box” I had built for a different project. (You might recognize it if you’re a regular here.) and added a solid state relay to control the heating element. I had already added the footprint for a MAX31855 Thermocouple to Digital IC on the board when I designed it (I was trying to make it a general purpose board) and it also has an XBee socket for a communications device. It was nothing to whip up some quick code to hold a temperature based on the thermocouple reading. Now I had to make it smarter.

I had a leftover RN-171 WiFly(tm) module in XBee form factor that I had removed from a paying project because it was so flaky it was almost useless. So, why not cause myself some more aggravation by using it in a “fun” project?

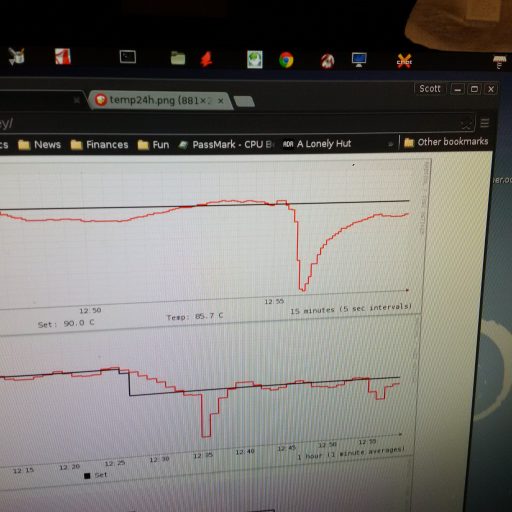

I added some quick code to send the current temperatures (both the thermocouple and the cold junction) to my home server every five seconds. My server could also respond with a new temperature setpoint. The server also stored the temperature and setpoint in an RRD database so it could make pretty graphs. It worked, but the WiFly kept falling off of the network, and required a restart before it would reconnect. If I got 20 minutes without it failing I was doing well. BUT, it DID hold the temperature much better than the stock Bradley did. But, it was still frustrating, so it ended up back in my garage for a bunch of months again.

With Thanksgiving coming up, and never one to shy away from trying something new, I decided to do a turkey in the smoker this weekend. I dug the smoker out of the garage and ensured that it could still hold a temperature. After doing that, I spent a few more hours on it and discovered a major firmware update to the WiFly module. I updated it, and it has been solid on the network for nearly 14 hours as I write this. Maybe Microchip has finally made this thing usable. Of course, with the availability of $3 ESP8266s they might be too late.

I brined a turkey over night and set it in the smoker using apple wood at about 9:30AM. At a setpoint of 107C, the inside thigh made it past the critical 140F in under 3.5 hours. It’s looking good!

Of course, when I opened the door to take the picture, the temperature in the smoker dipped:

UPDATE: I took the turkey out around 4:45PM and ate it. It was wonderful!