This is coming a bit late, but here are some projects I made at or mostly at techworks for halloween!

Aluminum Pumpkin

First up is a pumkin cut out of 5 bar aluminum and then filled with WS2812 LEDs for some RGB fun.

Next year I will make some spookier patterns for the leds.

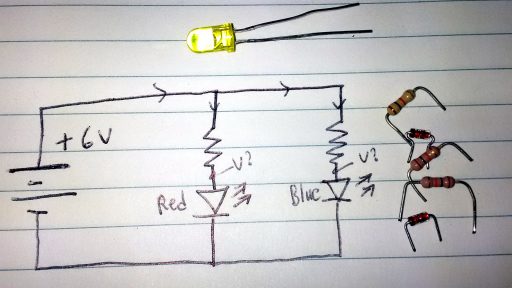

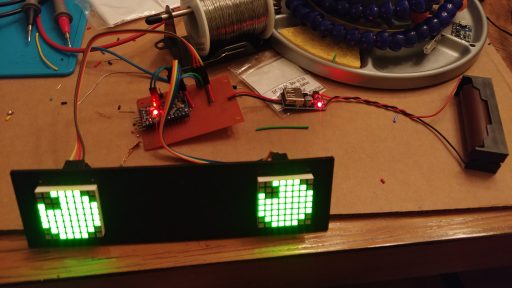

Angry Eyes

This was something I threw together pretty quick because I thought it was neat and would fit perfect in my mailbox. Couple 8×8 bi-color matrices mounted in a laser cut piece of acrylic, lithium battery, boost regulator and a arduino compatible micro board. Also added a motion sensor for interaction of the kids walking up the steps.

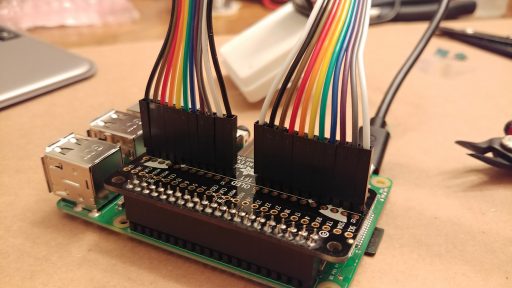

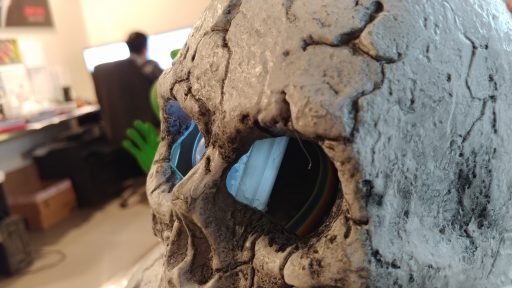

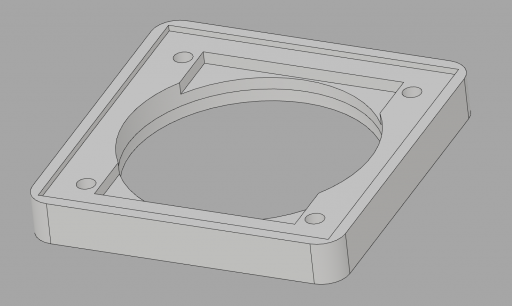

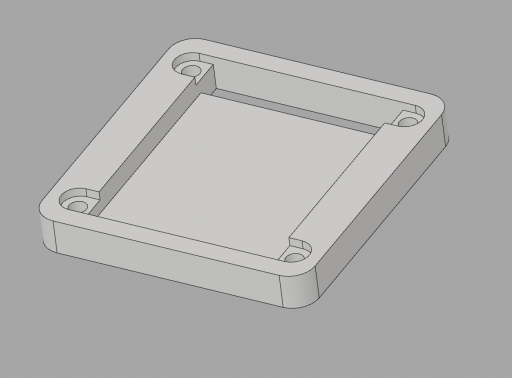

Skull Eyes

This one was real fun, and expensive. It’s the animated snake eyes bonnet and 240×240 LCDs from adafruit driven by an rpi3+. I bought some plastic half spheres on aliexpress and 3d printed some enclosures to put the screens together with the half spheres. I then very carefully hotglued these inside a skull decoration I picked up a few years ago from walmart. End result is pretty awesome.